Welcome to Nisarga Biotech, where nature meets innovation. Nestled on a sprawling 1-acre campus in Satara, just 250 kilometers from Mumbai, India and 2 kilometers from National highway 48, giving us excellent connectivity to sea and airports.

our state-of-the-art facility is a beacon of sustainable practices and cutting-edge technology in the manufacturing of botanical extracts. Specializing in nutraceuticals, cosmetics, aromatherapy, perfumery, and the food industry, we take pride in our commitment to quality, sustainability, and technological excellence.

At Nisarga Biotech, sustainability is not just a commitment; it’s a way of life. Our facility is adorned with solar panels on the roof, harnessing the power of the sun to meet 70% of our energy requirements. We go beyond by incorporating rainwater harvesting systems, ensuring responsible water usage and minimizing wastage. To further reduce our carbon footprint, our heating requirements are met through heat exchanger pumps, eliminating the need for fossil fuels or natural gas in our operations.

Our facility boasts a robust infrastructure capable of processing 450 metric tons of raw materials annually using advanced CO2 extraction technology. The versatility of our operation is enhanced by a fleet of four CO2 extraction machines:

Clean Rooms and Formulation Facilities:

To maintain the highest standards of product purity, we have incorporated dedicated clean rooms within our facility:

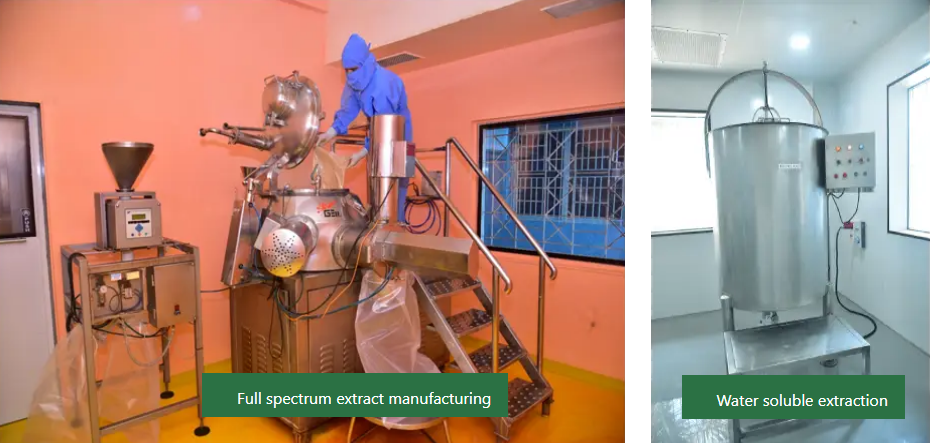

– 2 clean rooms for processing full spectrum extracts with a daily output of 1 metric ton each

– 1 clean room exclusively designed for processing water-soluble extracts, yielding a daily output of 3 metric tons

Additionally, we have two formulation rooms dedicated to blend manufacturing, ensuring precision and consistency in our final products.

Recognizing the importance of separating organic and conventional raw materials, our facility is equipped with distinct storage areas for both. This meticulous approach extends to our dispatch rooms, ensuring that organic and conventional products are handled and dispatched with the utmost care and compliance.

Innovation is at the core of Nisarga Biotech. Our 2500 sq. ft Research and Development Center stands testament to our dedication to advancing botanical extraction technologies. This facility is equipped with cutting-edge instruments, including:

– Atomic Absorption Spectrophotometer (AAS) for heavy metal analysis

– High-Performance Liquid Chromatographs (HPLC)

– Gas Chromatograph with headspace capabilities (GC)

– UV Spectrophotometer

– Fully equipped wet lab

– Pressure-controlled microbiology and cell line lab

Ensuring the highest standards of quality, our R&D center is supported by dedicated Quality Assurance and Quality Control labs. Our in-process QC lab is designed to monitor and maintain the quality of ongoing processes.

Nisarga Biotech stands as a beacon of excellence in botanical extraction, seamlessly blending nature’s gifts with cutting-edge technology.

Our commitment to sustainability, innovation, and quality is reflected in every aspect of our facility. From solar-powered operations to advanced CO2 extraction capabilities, we strive to redefine industry standards. Explore the world of botanical extracts with us, where purity, sustainability, and innovation converge.